Innovation

CEC’s key innovation is the substitution of recovered cement paste (RCP) for the lime used in the steel recycling process. Critically, CEC has proven that electric arc furnaces (EAFs) provide the right conditions to reactivate RCP extracted from old concrete waste, without interfering with the steelmaking. This co-production process avoids both the kiln-related energy and calcination process emissions from conventional cement production, and leverages existing steelmaking infrastructure.

Product

CEC’s cement product targets a direct replacement for current Portland Cement (i.e. a CEM I), delivering equivalent performance without the negative environmental impact.

Process

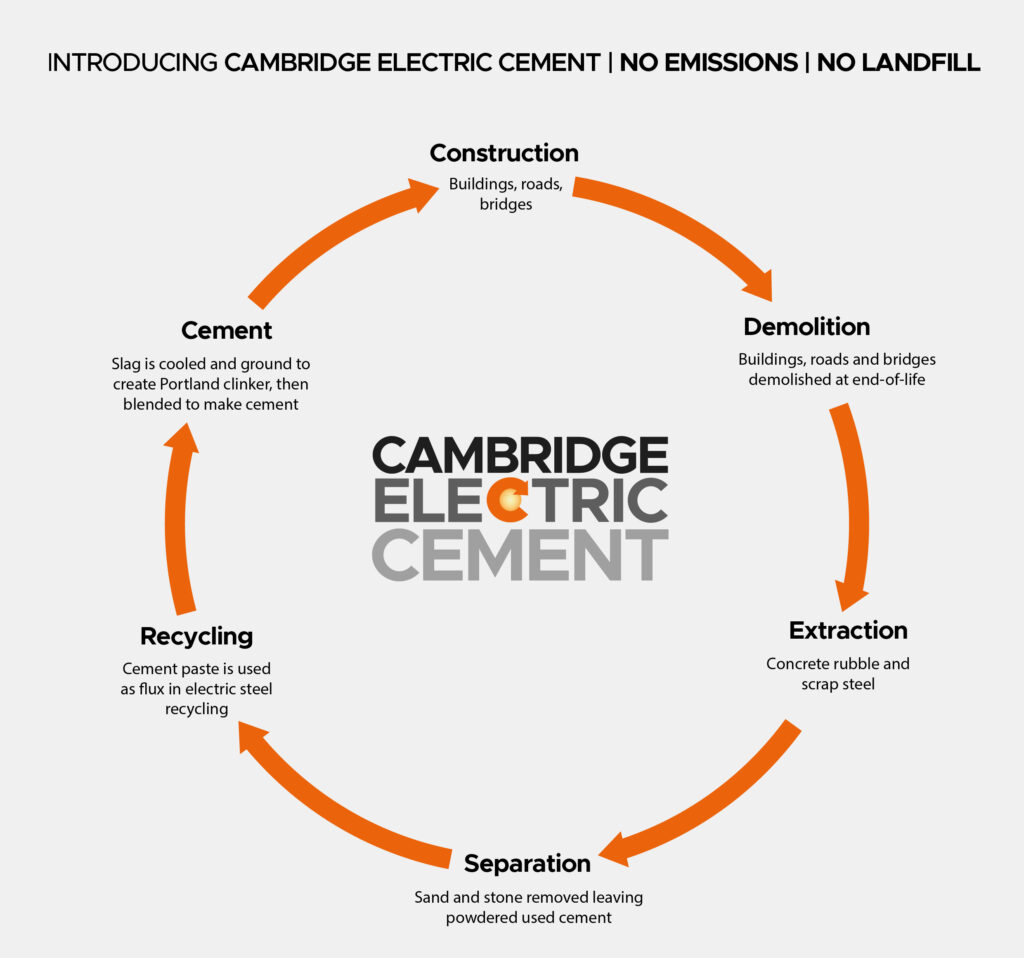

The Cambridge Electric Cement process begins with concrete waste from demolition of old buildings. This is crushed, to separate the stones and sand that form concrete from the mixture of cement powder and water that bind them together. The old cement powder is then used instead of lime-flux in steel recycling. As the steel melts, the flux forms a slag that floats on the liquid steel, to protect it from oxygen in the air. After the recycled steel is tapped off, the liquid slag is cooled rapidly in air, and ground up into a powder which is virtually identical to the clinker which is the basis of new Portland cement. In pilot-scale trials of the new process, the Cambridge team have demonstrated this combined recycling process, and the results show that it has the chemical composition of a clinker made with today’s process.